Monel 400

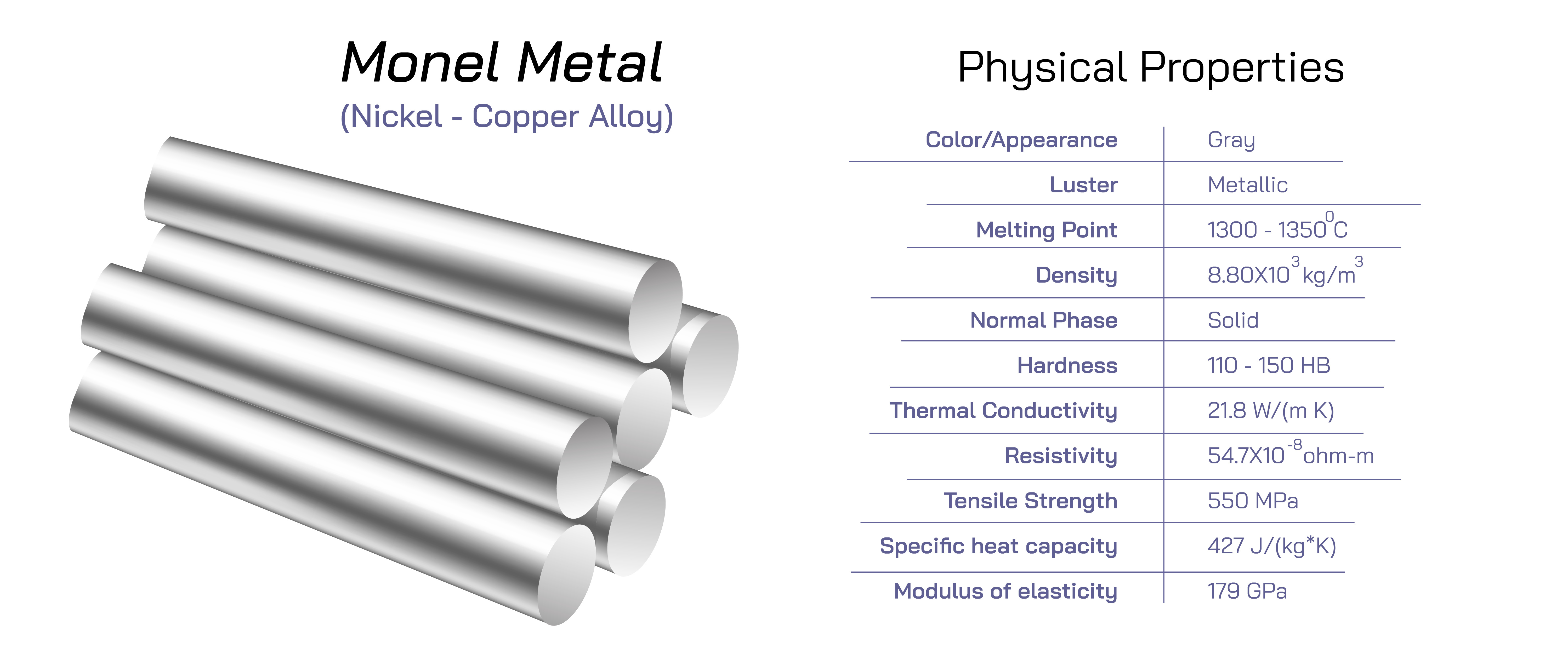

Monel 400 is a versatile and highly sought-after nickel-copper alloy known for its exceptional properties. Composed of approximately 67% nickel and 23% copper, with small amounts of iron, manganese, and silicon, Monel 400 offers a unique combination of corrosion resistance, high strength, and excellent durability. It is widely used in various industries, including marine, chemical, and aerospace, where it serves as an ideal material for applications that require resistance to corrosive environments, such as seawater and acidic solutions. Monel 400 exhibits excellent mechanical properties, making it suitable for high-temperature and high-pressure environments. Its notable features include good ductility, low coefficient of thermal expansion, and exceptional weldability. These characteristics and its resistance to stress corrosion cracking and pitting make Monel 400 popular for demanding applications requiring reliability and longevity.

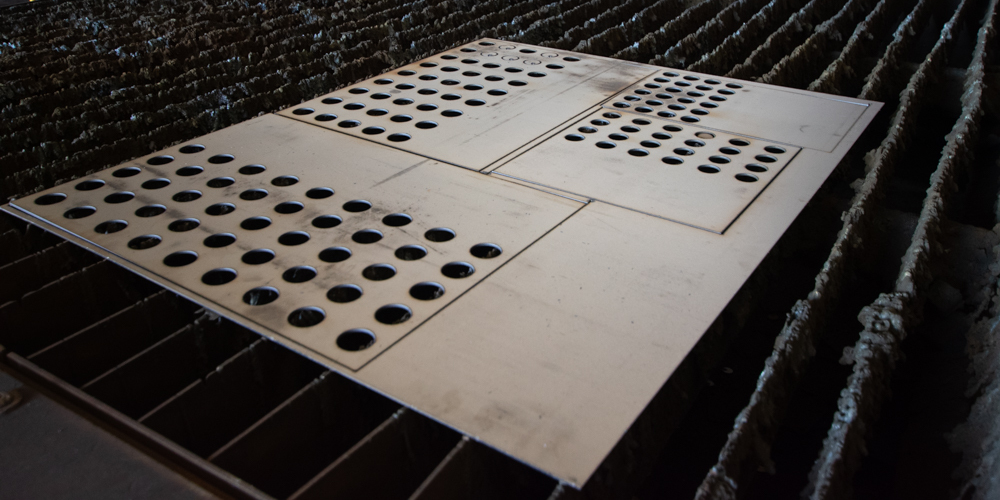

Pictured here are custom diffusers cut from Monel 400 on our plasma table. Plasma cutting offers numerous advantages over other cutting methods, including high cutting speeds, precise cutting capabilities, and the ability to cut through thick materials. This makes it an ideal choice for processing Monel steel, which can be challenging to cut with traditional methods due to its high strength. Steel Supply, L.P. ensures customers receive the highest quality custom Monel metal parts for specialized equipment, structural components, or intricate fabrications.