Custom Stud Welding

Specs and Features

- TRU‐WELD ARC Stud Guns

- We can weld studs up to 1.25 inches in diameter

- Frequently used in tilt-wall construction and for steel railings.

- Consistent, high-quality welds

- We can do it for you cheaper than you can do it by hand

Stud Welding

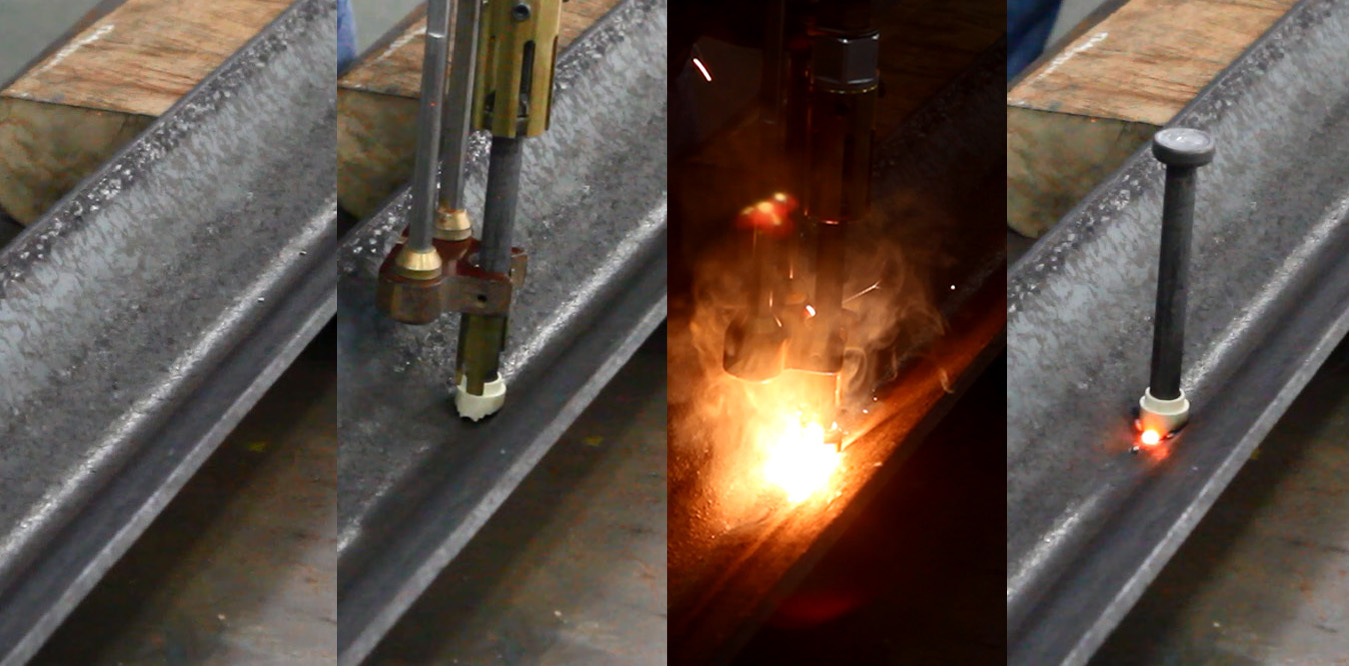

Specialized arc stud welding guns allow Steel Supply, L.P. to quickly produce consistent, high-quality stud welds in structural steel. High voltage is directed through the stud, generating an arc between the tip of the stud and the working surface. A ceramic collar is placed around the stud and the stud is loaded into the stud gun. When fired, an arc quickly melts the tip of the stud as well as the working surface. The stud is then plunged into the working surface fusing the two together. The ceramic collar around the tip of the stud directs the heat and contains the weld, ensuring a consistent bead around the point of contact. The weld cools quickly and the ceramic collar is broken off revealing a consistent, superior quality weld every time. This process takes about 10 seconds per weld!

Studs come in many forms and their consistency, speed, and security make them an ideal fastener solution in many industrial applications from petrochemical to construction. Studs welded on flat plates are called embed plates, frequently used in tilt-wall buildings. Wet concrete is formed over studs, leaving a steel plate on the surface. Embed plates allow concrete walls to be securely welded to a steel frame. When welded onto angles, embedded studs are often referred to as curb angles and are perfect for protecting concrete corners, such as on stairs or loading docks. Embedded studs are the best way to attach any steel shape to concrete.