Steel Bonded: Stud Welding for Connections

Stud welding has various forms to accommodate different applications, materials, and requirements.

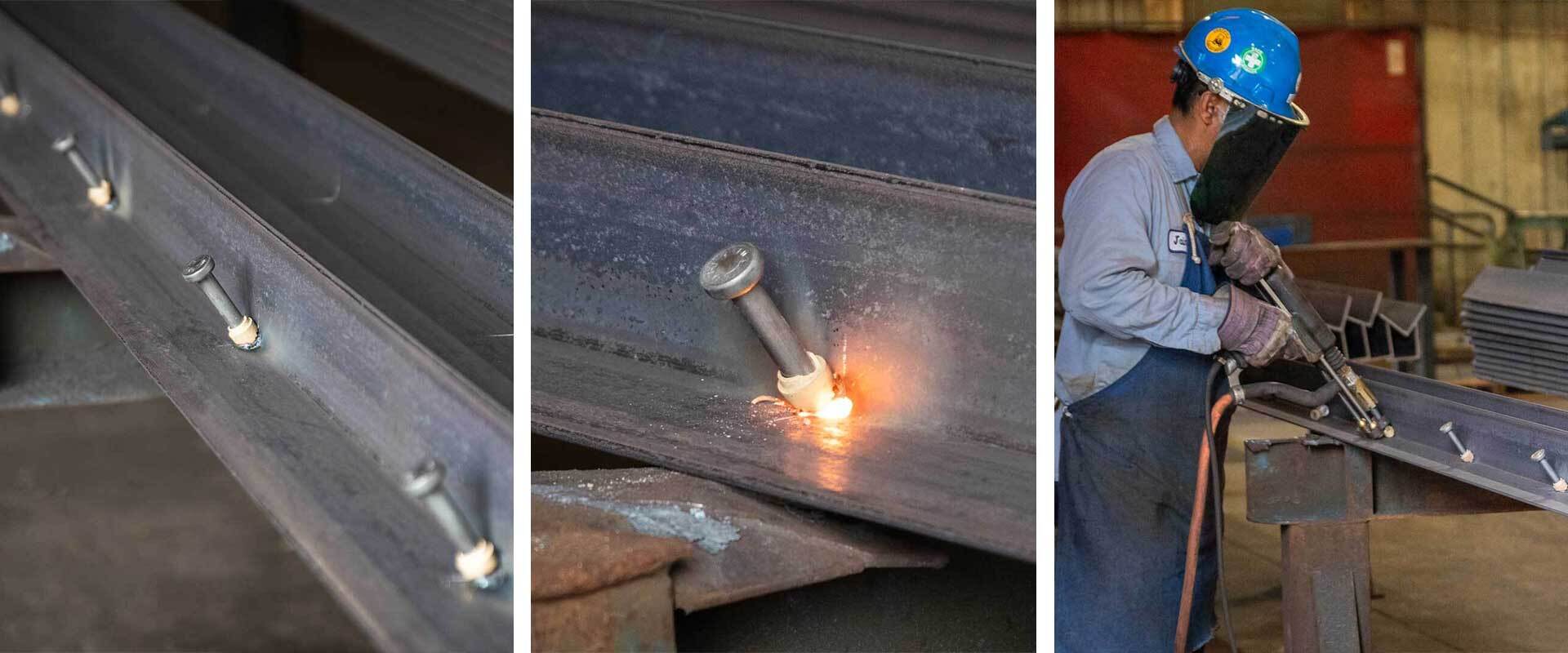

Stud welding involves joining a metal fastener, typically called a "stud," to a metal surface (in our case, angles). The process creates a permanent bond by fusing the base of the stud through an electric arc. When welded onto angles, embedded studs are often referred to as curb angles and are perfect for protecting concrete corners, such as on stairs or loading docks.

Positioning the Studs

First, we position the studs on the angles. For consistency, we use pre-marked templates across all angles.

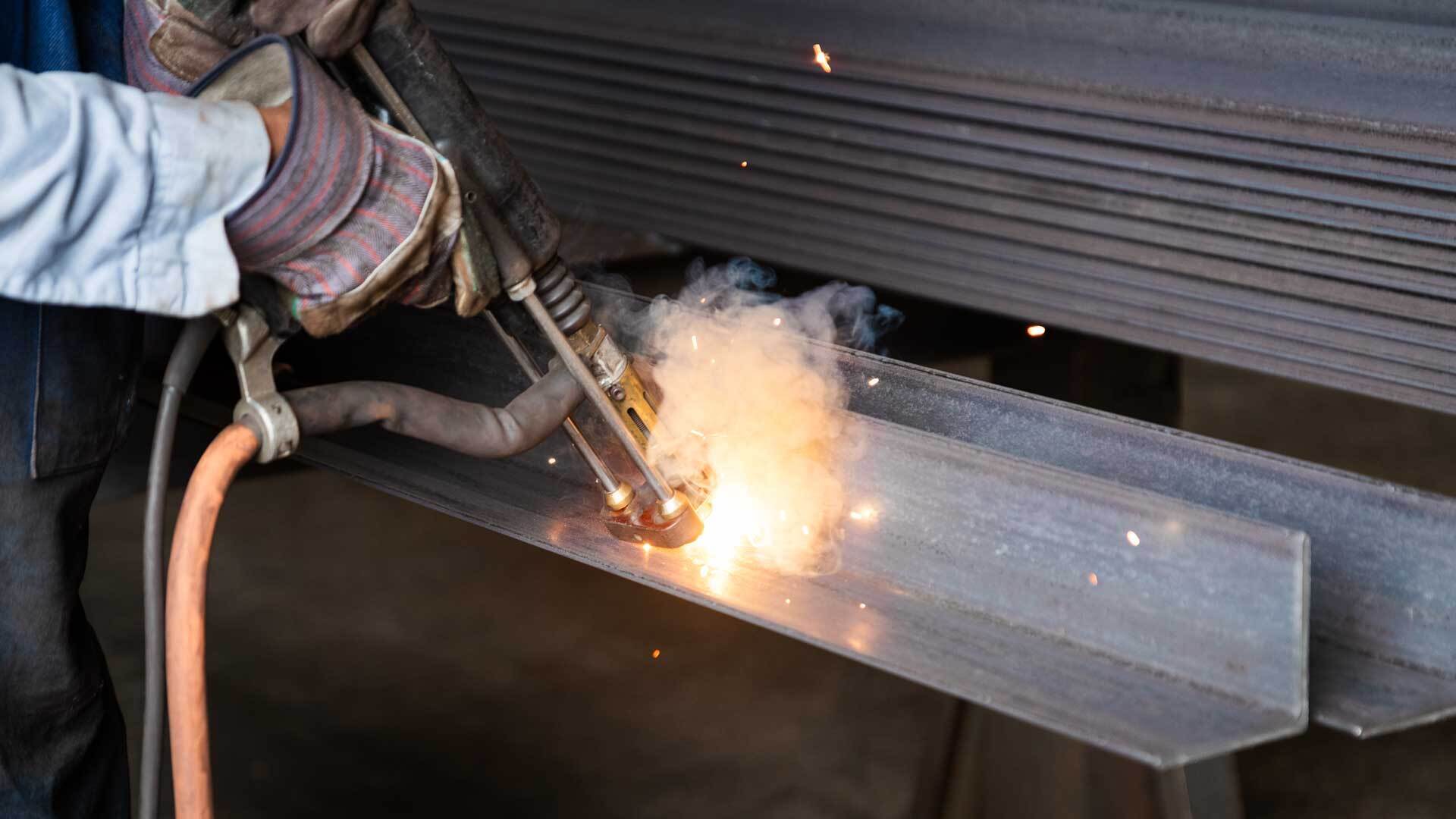

Welding the Studs

Once everything is in place, we start welding. The welding gun is placed over the stud and an electric arc forms when the trigger is pulled. This arc heats and melts the surfaces, and when the current stops, the stud is forced into the molten pool. The materials then cool and solidify, creating a bond.

Finishing and Coating

For this project, these curb angles were galvanized. A protective coating prevents corrosion and extends the lifespan, particularly in harsh conditions.

Helpful Links

Categories: Value-Added Projects